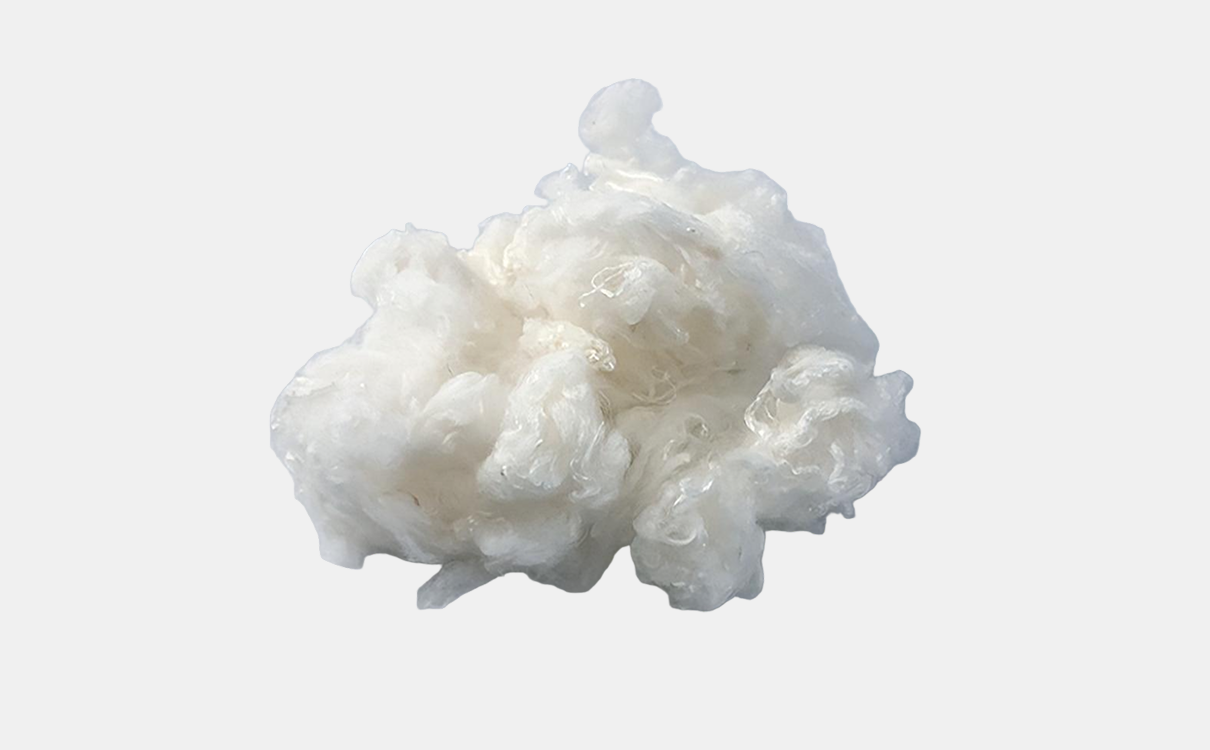

Staple Fiber series

Introducing our Staple Fiber Series, a comprehensive range of high-quality fibers designed to meet diverse textile and industrial needs.

Details

-

Category

-

Staple Fiber

Our Staple Fiber Series offers a comprehensive range of high-quality fibers designed to meet diverse textile and industrial needs. These fibers are characterized by their discrete lengths, making them ideal for spinning into yarns or forming non-woven fabrics. Our series includes various types of staple fibers, each engineered to provide specific properties and benefits.

Semi-Dull High-Strength Staple Fiber

Specifications: 1.56 dtex × 32 mm, 1.56 dtex × 38 mm, 1.33 dtex × 32 mm, 1.33 dtex × 38 mm, 1.56 dtex × 51 mm

Product Features: Exhibits excellent smoothness and quick-drying properties, high strength, good extensibility, stable dimensions, and superior combing and spinning performance. Fabrics produced are appropriately soft and durable.

Applications: Suitable for pure spinning or blending with other synthetic and natural fibers to create various fabrics. Applicable to ring spinning and air spinning; yarns can be used in both weaving and knitting.

Semi-Dull Spunlace Staple Fiber

Specifications: 1.56 dtex × 38 mm

Product Features: Offers good non-woven combing properties and hydrophilicity. Resistant to heat, light, wear, and acids, with excellent electrical insulation. Finished products demonstrate significant tearing and tensile strength advantages.

Applications: Used in non-woven sanitary materials such as straight-laid, semi-cross-laid, and cross-laid lines, as well as textiles like spunlace and filter nets.

Semi-Dull Medium and Long Staple Fiber

Specifications: 2.22 dtex × 51 mm, 2.78 dtex × 51 mm, 2.78 dtex × 65 mm

Physical Properties: Possesses good combing and spinning performance, heat resistance, light resistance, wear resistance, acid resistance, excellent electrical insulation, and high tensile strength. Capable of spinning coarse and medium yarns, and suitable for needle-punched non-woven products.

Applications: Used in thickened ring-spun products and specialty spinning products; also applicable for needle-punched non-woven products, non-woven filter materials, carpets, and industrial yarn products.

Semi-Dull Vortex Spinning Staple Fiber

Specifications: 1.33 dtex × 38 mm

Product Features: Demonstrates good hydrophilicity, certain moisture absorption and quick-drying properties, high strength, excellent combing and spinning performance, and good pilling and wear resistance after being processed into yarns.

Applications: Suitable for pure spinning or blending with other synthetic and natural fibers to produce various fabrics. Applicable to vortex spinning, ring spinning, and air spinning.

Three-Dimensional Siliconized Hollow Staple Fiber

Specifications: 3.33 dtex × 32 mm, 3.33 dtex × 51 mm, 3.33 dtex × 64 mm, 6.67 dtex × 32 mm, 6.67 dtex × 51 mm, 6.67 dtex × 64 mm, 16.67 dtex × 32 mm, 16.67 dtex × 51 mm, 16.67 dtex × 64 mm

Product Features: Features good smoothness, fluffiness, resilience, excellent thermal insulation, and superior filling and sound insulation properties. Can replace natural fibers and possesses the characteristics of chemical fibers, such as being resistant to mildew and moths.

Applications: Used in home textiles, sofa fillings, toy fillings, pillow fillings, and pearl cotton.

Three-Dimensional Non-Siliconized Hollow Staple Fiber

Specifications: 3.33 dtex × 64 mm, 6.67 dtex × 64 mm, 16.67 dtex × 64 mm

Product Features: Except for smoothness, it possesses all other product characteristics of three-dimensional siliconized hollow staple fiber.

Applications: Used in home textiles, spray-bonded cotton, glue-free cotton, and hard cotton.

These translations aim to maintain the professional tone and consistency of your original descriptions, aligning with industry standards.

Key Features:

Superior Smoothness and Quick-Drying Properties: Our semi-matte high-strength staple fibers offer excellent smoothness and quick-drying capabilities, making them suitable for a variety of textile applications.

High Strength and Extensibility: These fibers possess good strength and extensibility, ensuring durability and flexibility in the final products.

Stable Dimensions: The fibers maintain stable dimensions, providing consistency and reliability during processing and in the end-use applications.